|

| February 23, 2016 | Volume 12 Issue 08 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Flat, ultralight optical lens may open new world of design possibilities

University of Utah electrical and computer engineering professor Rajesh Menon holds up the prototype of the first flat, thin optical lens that he and his team developed. The new lens can be used in cameras and other devices such as smartphones where the lens does not have to jut out of the body. The lenses are simple to make using current manufacturing processes.

Imagine digital cameras or smartphones without the bulky lenses, or eyeglasses with lenses that are paper thin.

Researchers have always thought that flat, ultrathin optical lenses for cameras or other devices were impossible because of the way all the colors of light must bend through them. Consequently, photographers have had to put up with more cumbersome and heavier curved lenses. But University of Utah electrical and computer engineering professor Rajesh Menon and his team have developed a new method of creating optics that are flat and thin yet can still perform the function of bending light to a single point, the basic step in producing an image.

His findings were published Feb. 12 in a new paper, "Chromatic-Aberration-Corrected Diffractive Lenses for Ultra-Broadband Focusing," in Scientific Reports. The study was co-authored by University of Utah doctoral students Peng Wang and Nabil Mohammad.

"Instead of the lens having a curvature, it can be very flat so you get completely new design opportunities for imaging systems like the ones in your mobile phone," Menon says. "Our results correct a widespread misconception that flat, diffractive lenses cannot be corrected for all colors simultaneously."

In order to capture a photographic image in a camera or for your eyes to focus on an image through eyeglasses, the different colors of light must pass through the lenses and converge to a point on the camera sensor or on the eye's retina. How light bends through curved lenses is based on the centuries-old concept known as refraction, a principle that is similar to when you put a pencil in a glass of water and notice that it "bends" in the water. To do this, cameras typically will use a stack of multiple curved lenses in order to focus all of the colors of light to a single point. Multiple lenses are needed because different colors bend differently, and they are designed to ensure that all colors come to the same focus.

Menon and his team discovered a way to design a flat lens that can be 10 times thinner than the width of a human hair or millions of times thinner than a camera lens today. They do it through a principle known as diffraction in which light interacts with microstructures in the lens and bends.

"In nature, we see this when you look at certain butterfly wings. The color of the wings is from diffraction. If you look at a rainbow, it's from diffraction," he says. "What's new is we showed that we could actually engineer the bending of light through diffraction in such a way that the different colors all come to focus at the same point. That is what people believed could not be done."

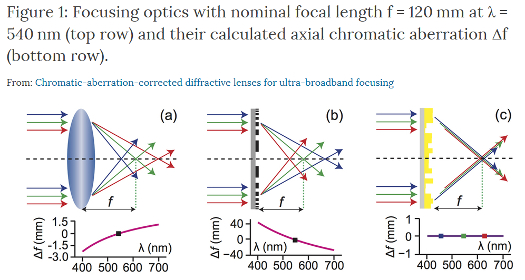

Normally incident uniform illumination is assumed. (a) Bi-convex refractive lens (BK7 glass). (b) Amplitude (binary) zone-plate. (c) Schematic explanation of the super-achromatic diffractive lens. Ideally, focus shift over the entire spectrum remains zero. [Credit: "Chromatic-Aberration-Corrected Diffractive Lenses for Ultra-Broadband Focusing," Scientific Reports, Feb. 2016]

Menon's researchers use specially created algorithms to calculate the geometry of a lens so different colors can pass through it and focus to a single point. The resulting lens, called a "super-achromatic lens," can be made of any transparent material such as glass or plastic.

"The lens is made via optical lithography in my lab. In the future, it can be easily made by stamping processes such as used for CDs or DVDs," Menon told Designfax. At its most basic explanation, incredibly precise square or linear grooves are made in the material to form an overall diffraction pattern in the focal plane. The grooves are so miniscule that they cannot be seen by the naked eye.

According to the Scientific Reports paper the aberration-correction capabilities of these lenses "are on par with -- or better than -- commercial doublets [lenses]."

Other applications of this potential lens system include medical devices in which thinner and lighter endoscopes can peer into the human body. It also could be used for drones or satellites with lighter cameras in which reducing weight is critical. Future smartphones could come with high-powered cameras that don't require the lens jutting out from the phone's thin body, such as the lens does now for the iPhone 6S.

Now that Menon and his team have proved the concept can work, he believes the first applications of their research could become a reality within five years.

Source: University of Utah

Published February 2016

Rate this article

View our terms of use and privacy policy